3535 rgb smd led

- Category: 2016 SMD LED

- Brand:ARKTECH

- delivery date: 7 to 9 working days

- payment method: We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit)

- Our team offers all-round technical support, including designing according to your requirements, selecting the best solutions based on cost and reliability, principle and LAY-OUT design, customizing s

One of our key strengths is our state-of-the-art facility, which boasts a 12000㎡ dust-free and antistatic standard workshop. This ensures that our manufacturing process is of the highest quality, resulting in superior products that meet the highest industry standards.

| Product name | 3535 rgb smd led |

| Keyword | 5630 smd led pcb,smd led lumens,0402 smd led blue,dialight smd led,china odm surface mount smd led,smd led markings |

| Place of Origin | China |

| Brand | ARKTECH |

| Current | 86MA |

| Power | 1.3W |

| Voltage | 1.3V |

| Raw material | Copper bracket/ pure gold wire |

| Quantity | 2279pcs/reel |

| Dimensions | 5.5mm*5.3mm*1.9mm, (Contact us for specific information to confirm) |

| Applicable Industries | monitoring aids, etc. |

| Color | Brown |

| Weight | 20mg |

| Product Description | SMD LED 5054 High Voltage Linear Cold White,48 smd led wattage,0.2 w 2835 smd led,0403 smd led,3w red smd led,48 smd led-It is a new surface packaging technology that encapsulates LED chips in tiny weldable packaging films and performs surface spot welding on the PCB substrate, thus improving the reliability and production efficiency of LEDs. Compared with traditional LED packaging, SMD LED has the advantages of small size, large light-emitting area, high power, low packaging height, and multiple color temperatures, and can greatly reduce costs through automated production processes. |

| delivery date | Our standard delivery time is 7 to 9 working days. |

| payment method | We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit). |

| Life span | 52688 + hours (Contact us for specific information to confirm) |

| warranty | We provide a warranty period of 2 years |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Packing | 12x9.02x12mm(Contact us for specific information to confirm) |

| Sales country | All over the world for example:Bahamas, The,Vanuatu,Gibraltar,Antigua and Barbuda,Northern Mariana Islands,Mauritania,Uruguay,Iraq |

| MOQ | 8 reel(Contact us for specific information to confirm) |

| customization services | We welcome customization requests for our products |

| production capacity | We have the capacity to produce 89kk pieces of LEDs per month. |

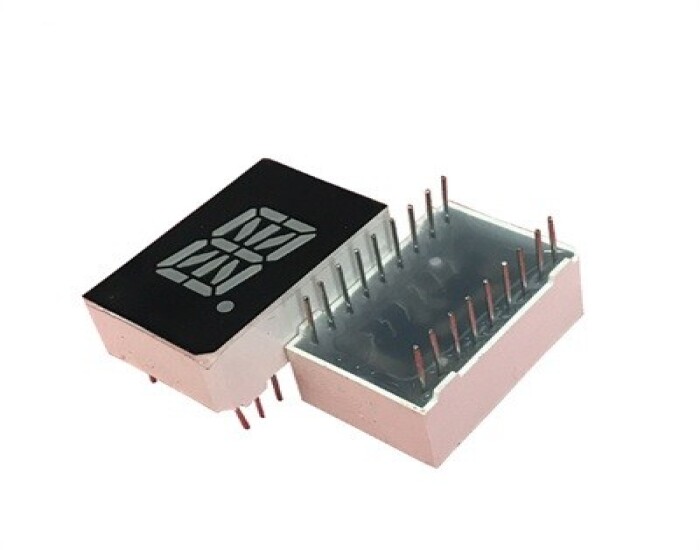

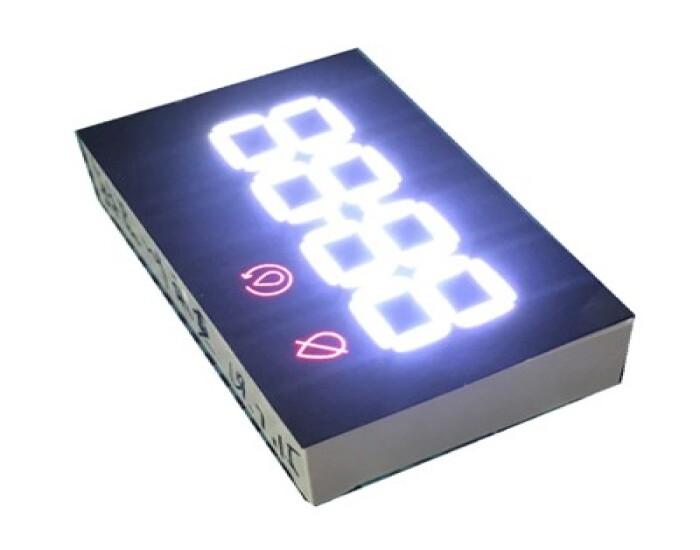

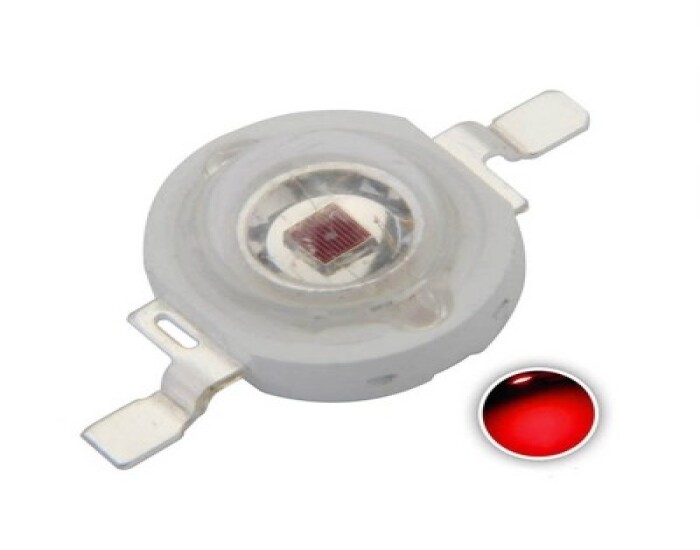

Segment led display, Custom LED display, Through hole LED, High power LED(Please contact us for specific information about Segment led display)

3535 rgb smd led services FAQs Guide

Are you looking for a quick review guide about 3535 rgb smd ledservices?

An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding 3535 rgb smd led services.

Let’s continue!

2.What is the typical power consumption of 3535 rgb smd led?

3.What is the viewing angle of 3535 rgb smd led?

4.What is the installation process for 3535 rgb smd led?

5.Is 3535 rgb smd led resistant to shock and vibration?

6.Are there any size limitations for 3535 rgb smd led?

7.How does 3535 rgb smd led handle heat dissipation?

8.What are the benefits of using 3535 rgb smd led technology?

9.Are there any maintenance requirements for 3535 rgb smd led?

10.Can 3535 rgb smd led be used in hazardous locations?

11.About 3535 rgb smd led production skills training

12.How do 3535 rgb smd led lights differ from traditional LEDs?

1.About 3535 rgb smd led raw material procurement system

Our production process is closely monitored through an ERP system and MES system, ensuring the stability and traceability of our products.

2.What is the typical power consumption of 3535 rgb smd led?

3535 rgb smd led is not a product only, but also can help you comes to money-making.

The typical power consumption of SMD LED varies depending on the size and type of the LED. Generally, the power consumption can range from 0.05 watts to 1 watt per LED. However, some high-power SMD LEDs can consume up to 5 watts. It is important to check the specifications of the specific SMD LED to determine its power consumption.

3.What is the viewing angle of 3535 rgb smd led?

We are a new 3535 rgb smd led manufacturer.

The viewing angle of SMD LED can vary depending on the specific model and manufacturer, but it is typically between 120-180 degrees. This means that the light emitted from the LED can be seen from a wide angle, making it suitable for use in applications where a broad and even distribution of light is desired.

4.What is the installation process for 3535 rgb smd led?

Our mission is to provide customers with the best solutions for 3535 rgb smd led.

1. Gather Materials: Before starting the installation process, make sure you have all the necessary materials including the SMD LED lights, power supply, soldering iron, solder, wire strippers, and heat shrink tubing.

2. Plan the Layout: Decide on the placement of the SMD LED lights and plan the wiring layout accordingly. Make sure to measure the distance between each light and the power supply to determine the length of wire needed.

3. Prepare the Surface: Clean the surface where the SMD LED lights will be installed to ensure a strong and secure bond. If the surface is rough, use sandpaper to smooth it out.

4. Solder the Wires: Strip the ends of the wires and solder them to the positive and negative terminals of the SMD LED lights. Make sure to match the polarity of the wires to the correct terminals on the lights.

5. Connect the Lights: Once all the wires are soldered, connect them to the power supply. The positive wire should be connected to the positive terminal and the negative wire to the negative terminal.

6. Secure the Wires: Use heat shrink tubing to cover the soldered connections and secure them in place. This will prevent any short circuits and ensure a clean and professional look.

7. Test the Lights: Before permanently installing the lights, test them to make sure they are working properly. If there are any issues, double check the connections and fix any problems before proceeding.

8. Install the Lights: Once the lights are tested and working, use adhesive tape or glue to secure them in place. Make sure to follow the manufacturer's instructions for the best adhesive to use for your specific surface.

9. Connect to Power: Plug the power supply into a wall outlet and turn on the lights to make sure they are working correctly.

10. Clean Up: Once the installation is complete, clean up any excess wires and materials. Enjoy your newly installed SMD LED lights!

5.Is 3535 rgb smd led resistant to shock and vibration?

We have the leading technology and innovation capabilities, and attach importance to employee training and development, and provide promotion opportunities.

Yes, SMD LED (Surface Mount Device Light Emitting Diode) is generally resistant to shock and vibration. This is because SMD LEDs are mounted directly onto a circuit board, which provides stability and protection against external forces. Additionally, SMD LEDs do not have any moving parts, making them less susceptible to damage from shock and vibration. However, excessive or prolonged shock and vibration can still potentially damage SMD LEDs, so it is important to handle them with care.

6.Are there any size limitations for 3535 rgb smd led?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

There are no specific size limitations for SMD LED, as they can be manufactured in various sizes and shapes to suit different applications. However, the smaller the size of the LED, the more challenging it is to manufacture and handle, which can affect its performance and reliability. Generally, SMD LEDs range from 0.2mm to 5mm in size.

7.How does 3535 rgb smd led handle heat dissipation?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced 3535 rgb smd led products.

SMD (Surface Mount Device) LED chips are designed to handle heat dissipation in several ways:

1. Heat Sink: SMD LEDs are often mounted on a heat sink, which is a metal plate or structure that helps to dissipate heat away from the LED chip. The heat sink provides a larger surface area for heat to dissipate, allowing the LED to operate at a lower temperature.

2. Thermal Pad: Some SMD LEDs have a thermal pad on the bottom of the chip, which helps to transfer heat away from the LED and onto the heat sink.

3. Thermal Via: SMD LEDs may also have thermal vias, which are small holes in the PCB (printed circuit board) that allow heat to transfer from the LED chip to the other side of the board, where it can be dissipated.

4. Copper Traces: The PCB may also have copper traces that act as heat sinks, helping to dissipate heat away from the LED chip.

5. Encapsulation: SMD LEDs are often encapsulated in a material that helps to dissipate heat, such as silicone or epoxy. This material also protects the LED chip from external factors that could affect its performance.

Overall, SMD LEDs are designed to efficiently dissipate heat and maintain a low operating temperature, which helps to prolong their lifespan and maintain their performance.

8.What are the benefits of using 3535 rgb smd led technology?

We maintain a stable growth through reasonable capital operations, focus on industry development trends and cutting -edge technologies, and focus on product quality and safety performance.

1. Energy Efficiency: SMD LEDs are highly energy-efficient, consuming up to 80% less energy than traditional incandescent bulbs. This makes them a cost-effective option for lighting.

2. Long Lifespan: SMD LEDs have a longer lifespan compared to traditional bulbs, lasting up to 50,000 hours or more. This means they require less frequent replacements, reducing maintenance costs.

3. Compact Size: SMD LEDs are small in size, making them ideal for use in compact electronic devices such as smartphones, laptops, and TVs. They also allow for more flexibility in design and can be used in a variety of applications.

4. Brightness: SMD LEDs produce bright and uniform light, making them suitable for use in a wide range of lighting applications, from task lighting to ambient lighting.

5. Low Heat Emission: SMD LEDs emit very little heat, making them safe to use in close proximity to heat-sensitive materials or in confined spaces.

6. Durability: SMD LEDs are more durable than traditional bulbs as they are not made of fragile materials like glass. They are also resistant to shock and vibrations, making them suitable for use in rugged environments.

7. Instant On: SMD LEDs light up instantly without any warm-up time, unlike traditional bulbs that take a few seconds to reach full brightness.

9.Are there any maintenance requirements for 3535 rgb smd led?

We focus on providing high 3535 rgb smd led quality products and services.

Yes, there are some maintenance requirements for SMD LED:

1. Regular cleaning: Dust and dirt can accumulate on the surface of SMD LED, affecting its brightness and performance. It is important to regularly clean the LED with a soft, dry cloth to remove any dust or dirt.

2. Avoid moisture: SMD LED is sensitive to moisture and can get damaged if exposed to excessive moisture. It is important to keep the LED dry and avoid any contact with water.

3. Check for loose connections: SMD LED is soldered onto a circuit board, and over time, the connections can become loose due to vibrations or temperature changes. It is important to regularly check for loose connections and re-solder them if necessary.

4. Monitor heat dissipation: SMD LED can generate heat, and if not dissipated properly, it can affect its performance and lifespan. It is important to ensure that the LED is installed in a well-ventilated area and that any heat generated is dissipated efficiently.

5. Replace faulty LEDs: If any SMD LED is not functioning properly or has burnt out, it is important to replace it with a new one to maintain the overall performance of the LED system.

6. Follow manufacturer's instructions: It is important to follow the manufacturer's instructions for maintenance and care of SMD LED to ensure its optimal performance and longevity.

10.Can 3535 rgb smd led be used in hazardous locations?

We enjoy high authority and influence in the industry and continue to innovate products and service models.

No, SMD LED cannot be used in hazardous locations as they are not designed to withstand the potential risks and dangers present in these environments. Hazardous locations are defined as areas where flammable gases, vapors, or dusts may be present, and SMD LED may not have the necessary certifications or protections to operate safely in these conditions. It is important to use LED lighting specifically designed and certified for hazardous locations in these environments to ensure safety and compliance with regulations.

11.About 3535 rgb smd led production skills training

We require all our employees to undergo three months of training. Only after successfully passing a qualified test are they allowed to work on the production line. To further ensure the quality of our goods, we have implemented diagrams along the production line, providing clear instructions and guidelines. Additionally, our HD engineers conduct monthly training sessions to keep our team updated with the latest production techniques and practices.

12.How do 3535 rgb smd led lights differ from traditional LEDs?

Our products & services cover a wide range of areas and meet the needs of different fields.

SMD (Surface Mount Device) LED lights are a type of LED that is mounted directly onto a circuit board, rather than being encased in a traditional bulb or package. This allows for a smaller and more compact design, as well as improved heat dissipation and durability.

Some other differences between SMD LED lights and traditional LEDs include:

1. Size and shape: SMD LEDs are typically smaller and flatter than traditional LEDs, making them more versatile for use in various applications.

2. Brightness: SMD LEDs are generally brighter than traditional LEDs, as they can be packed more closely together on a circuit board.

3. Energy efficiency: SMD LEDs are more energy-efficient than traditional LEDs, as they require less power to produce the same amount of light.

4. Viewing angle: SMD LEDs have a wider viewing angle than traditional LEDs, meaning they can emit light in a broader direction.

5. Cost: SMD LEDs are typically more expensive than traditional LEDs, due to their advanced technology and manufacturing process.

6. Color options: SMD LEDs offer a wider range of color options than traditional LEDs, including RGB (red, green, blue) and RGBW (red, green, blue, white) options.

Overall, SMD LED lights offer improved performance and versatility compared to traditional LEDs, making them a popular choice for various lighting applications.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Ms.Wendy

Mobile:0086-15861679389

Tel:0086-81725657

Whatsapp:0086 17386542651

Email:info@arktechcn.com

Add:8# HengDa CaiFu Center, JinKai Industrial Area, Wuci City, Jiang Su, China