5050 smd led schematic

- Category: 2016 SMD LED

- Brand:ARKTECH

- delivery date: 7 to 9 working days

- payment method: We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit)

- Our team offers all-round technical support, including designing according to your requirements, selecting the best solutions based on cost and reliability, principle and LAY-OUT design, customizing s

| Product name | 5050 smd led schematic |

| Keyword | 1206 smd led blue,smd led lights,250 lumen 18 smd led work light,multicolor smd led,56 smd led lighted magnifying lamp,angel eyes smd led |

| Place of Origin | China |

| Brand | ARKTECH |

| Current | 121MA |

| Power | 1.5W |

| Voltage | 0.8V |

| Raw material | Copper bracket/ pure gold wire |

| Quantity | 2204pcs/reel |

| Dimensions | 4.5mm*3.8mm*1.4mm, (Contact us for specific information to confirm) |

| Applicable Industries | household appliances, etc. |

| Color | purple |

| Weight | 10mg |

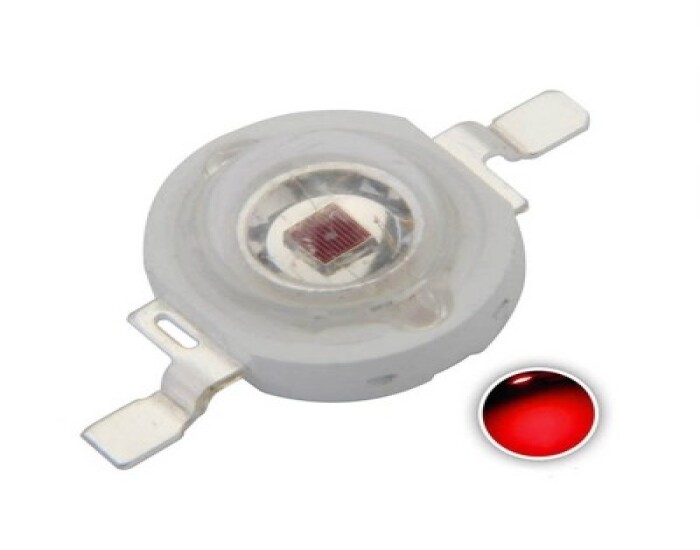

| Product Description | SMD LED 5054 High Voltage Linear Cold White,0.5w smd led 3.v,4 leg smd led,SMD 5630 LED Grow plant light 660nm light-It is a new surface packaging technology that encapsulates LED chips in tiny weldable packaging films and performs surface spot welding on the PCB substrate, thus improving the reliability and production efficiency of LEDs. Compared with traditional LED packaging, SMD LED has the advantages of small size, large light-emitting area, high power, low packaging height, and multiple color temperatures, and can greatly reduce costs through automated production processes. |

| delivery date | Our standard delivery time is 7 to 9 working days. |

| payment method | We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit). |

| Life span | 51634 + hours (Contact us for specific information to confirm) |

| warranty | We provide a warranty period of 2 years |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Packing | 16x8.62x11.2mm(Contact us for specific information to confirm) |

| Sales country | All over the world for example:Martinique,Guatemala,Dominica,Tromelin Island,Comoros,Solomon Islands |

| MOQ | 6 reel(Contact us for specific information to confirm) |

| customization services | We welcome customization requests for our products |

| production capacity | We have the capacity to produce 91kk pieces of LEDs per month. |

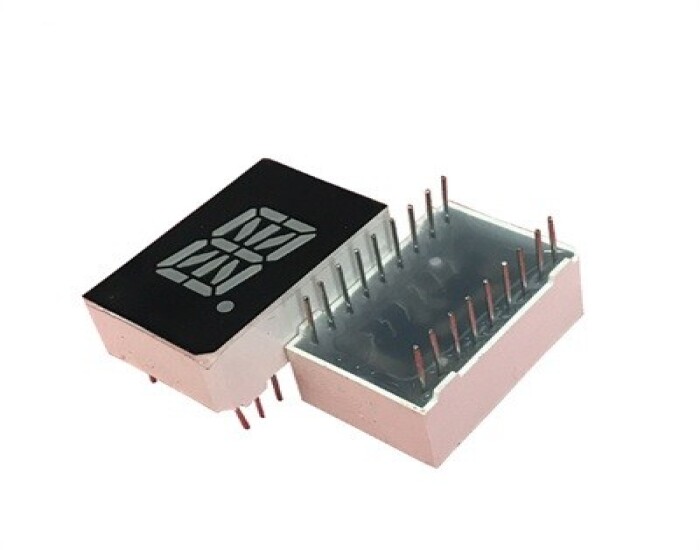

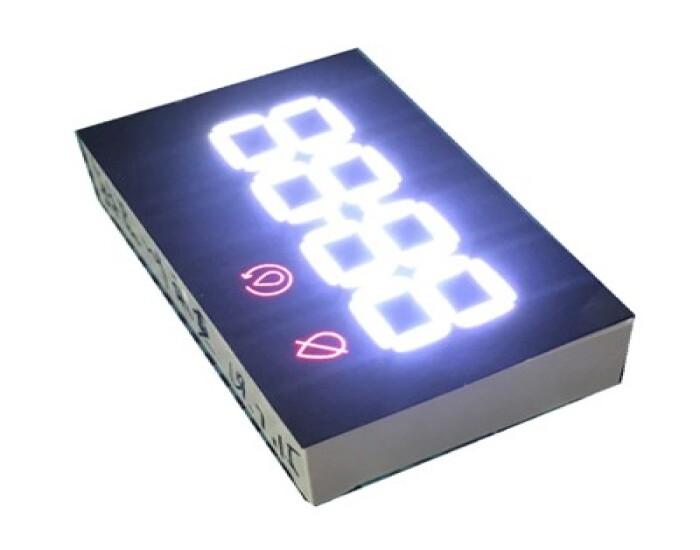

Segment led display, Custom LED display, Through hole LED, High power LED(Please contact us for specific information about Segment led display)

5050 smd led schematic services FAQs Guide

Are you looking for a quick review guide about 5050 smd led schematicservices?

An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding 5050 smd led schematic services.

Let’s continue!

2.Can 5050 smd led schematic be used in hazardous locations?

3.About 5050 smd led schematic quality system

4.How does the luminous efficacy of 5050 smd led schematic compare to other LEDs?

5.Can 5050 smd led schematic be used in conjunction with smart lighting systems?

6.How does the color temperature of 5050 smd led schematic affect its use?

7.About the scale of 5050 smd led schematic factory

8.About 5050 smd led schematic production equipment

9.What are the advantages of using 5050 smd led schematic lights?

10.What is the installation process for 5050 smd led schematic?

1.Are 5050 smd led schematics energy efficient?

We pay attention to the transformation of intellectual property protection and innovation achievements. Your OEM or ODM order design we have a complete confidentiality system.

Yes, SMD LEDs (Surface Mount Device Light Emitting Diodes) are energy efficient. They use significantly less energy than traditional incandescent or fluorescent bulbs, making them a popular choice for energy-conscious consumers. SMD LEDs also have a longer lifespan, further contributing to their energy efficiency.

2.Can 5050 smd led schematic be used in hazardous locations?

We enjoy high authority and influence in the industry and continue to innovate products and service models.

No, SMD LED cannot be used in hazardous locations as they are not designed to withstand the potential risks and dangers present in these environments. Hazardous locations are defined as areas where flammable gases, vapors, or dusts may be present, and SMD LED may not have the necessary certifications or protections to operate safely in these conditions. It is important to use LED lighting specifically designed and certified for hazardous locations in these environments to ensure safety and compliance with regulations.

3.About 5050 smd led schematic quality system

Our factory operates on an ERP system, which allows for efficient management and coordination of our operations. In addition, we are proud to have obtained ISO9001 certification, demonstrating our commitment to quality and customer satisfaction.

4.How does the luminous efficacy of 5050 smd led schematic compare to other LEDs?

We should enjoy a good reputation in the industry, and we can increase the added value of the products of cooperative customers through technological innovation.

SMD (Surface Mount Device) LEDs have a higher luminous efficacy compared to other types of LEDs. This is because SMD LEDs have a smaller size and can be densely packed on a circuit board, allowing for more efficient use of light output. Additionally, SMD LEDs have a higher color rendering index (CRI) which means they can produce a wider range of colors and more accurate color representation. Overall, SMD LEDs have a luminous efficacy that is comparable to other high-efficiency LEDs such as COB (Chip on Board) and high-power LEDs.

5.Can 5050 smd led schematic be used in conjunction with smart lighting systems?

We focus on innovation and continuous improvement to maintain a competitive advantage.

Yes, SMD LED can be used in conjunction with smart lighting systems. SMD LED technology is commonly used in smart lighting systems due to its small size, energy efficiency, and ability to produce a wide range of colors. SMD LED can be controlled and dimmed using smart lighting controllers and can be integrated into smart home automation systems for remote control and scheduling. Additionally, SMD LED can be used in smart lighting systems that utilize sensors and motion detectors for energy-saving and automated lighting control.

6.How does the color temperature of 5050 smd led schematic affect its use?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

The color temperature of SMD LED affects its use in several ways:

1. Color appearance: The color temperature of an SMD LED determines the color appearance of the light it emits. A lower color temperature (2700K-3000K) produces warm white light, while a higher color temperature (5000K-6500K) produces cool white light. This can affect the ambiance and mood of a space, as well as the visibility and clarity of objects under the light.

2. Application suitability: The color temperature of an SMD LED can make it more suitable for certain applications. For example, warm white light is often preferred for residential and hospitality settings, while cool white light is more suitable for commercial and industrial settings.

3. Color rendering: The color temperature of an SMD LED can also affect its color rendering index (CRI), which is a measure of how accurately the light source renders colors compared to natural light. A higher color temperature can result in a higher CRI, making colors appear more vibrant and true to life.

4. Energy efficiency: The color temperature of an SMD LED can also impact its energy efficiency. Generally, higher color temperatures require more energy to produce, so a lower color temperature may be more energy-efficient.

5. Human health: The color temperature of an SMD LED can also have an impact on human health. Exposure to cool white light with a high color temperature at night can disrupt the body's natural sleep-wake cycle, while warm white light with a lower color temperature is less likely to have this effect.

Overall, the color temperature of an SMD LED is an important factor to consider when choosing the right lighting for a specific application, as it can affect the appearance, suitability, energy efficiency, and potential health impacts of the light.

7.About the scale of 5050 smd led schematic factory

Our factory covers an area of 12000㎡, including a 600㎡ 10k class dust-free, anti-static workshop.

8.About 5050 smd led schematic production equipment

Our factory comprises three production departments, housing a total of 12 production lines. We have equipped these lines with over 120 automatic machines from renowned brands such as ASM and Kaijo.

9.What are the advantages of using 5050 smd led schematic lights?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously.

1. Compact Size: SMD LEDs are smaller in size compared to traditional LEDs, making them ideal for use in compact electronic devices and applications.

2. Energy Efficiency: SMD LEDs are highly energy-efficient, consuming less power and producing more light output compared to traditional LEDs.

3. Brightness: SMD LEDs are brighter than traditional LEDs, making them suitable for use in applications where high brightness is required.

4. Durability: SMD LEDs are more durable and have a longer lifespan compared to traditional LEDs, making them a cost-effective option in the long run.

5. Versatility: SMD LEDs come in a variety of sizes, shapes, and colors, making them suitable for a wide range of applications, including lighting, displays, and indicators.

6. Heat Dissipation: SMD LEDs have a better heat dissipation system, which helps to keep the temperature of the LED low, resulting in better performance and longer lifespan.

10.What is the installation process for 5050 smd led schematic?

Our mission is to provide customers with the best solutions for 5050 smd led schematic.

1. Gather Materials: Before starting the installation process, make sure you have all the necessary materials including the SMD LED lights, power supply, soldering iron, solder, wire strippers, and heat shrink tubing.

2. Plan the Layout: Decide on the placement of the SMD LED lights and plan the wiring layout accordingly. Make sure to measure the distance between each light and the power supply to determine the length of wire needed.

3. Prepare the Surface: Clean the surface where the SMD LED lights will be installed to ensure a strong and secure bond. If the surface is rough, use sandpaper to smooth it out.

4. Solder the Wires: Strip the ends of the wires and solder them to the positive and negative terminals of the SMD LED lights. Make sure to match the polarity of the wires to the correct terminals on the lights.

5. Connect the Lights: Once all the wires are soldered, connect them to the power supply. The positive wire should be connected to the positive terminal and the negative wire to the negative terminal.

6. Secure the Wires: Use heat shrink tubing to cover the soldered connections and secure them in place. This will prevent any short circuits and ensure a clean and professional look.

7. Test the Lights: Before permanently installing the lights, test them to make sure they are working properly. If there are any issues, double check the connections and fix any problems before proceeding.

8. Install the Lights: Once the lights are tested and working, use adhesive tape or glue to secure them in place. Make sure to follow the manufacturer's instructions for the best adhesive to use for your specific surface.

9. Connect to Power: Plug the power supply into a wall outlet and turn on the lights to make sure they are working correctly.

10. Clean Up: Once the installation is complete, clean up any excess wires and materials. Enjoy your newly installed SMD LED lights!

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Ms.Wendy

Mobile:0086-15861679389

Tel:0086-81725657

Whatsapp:0086 17386542651

Email:info@arktechcn.com

Add:8# HengDa CaiFu Center, JinKai Industrial Area, Wuci City, Jiang Su, China