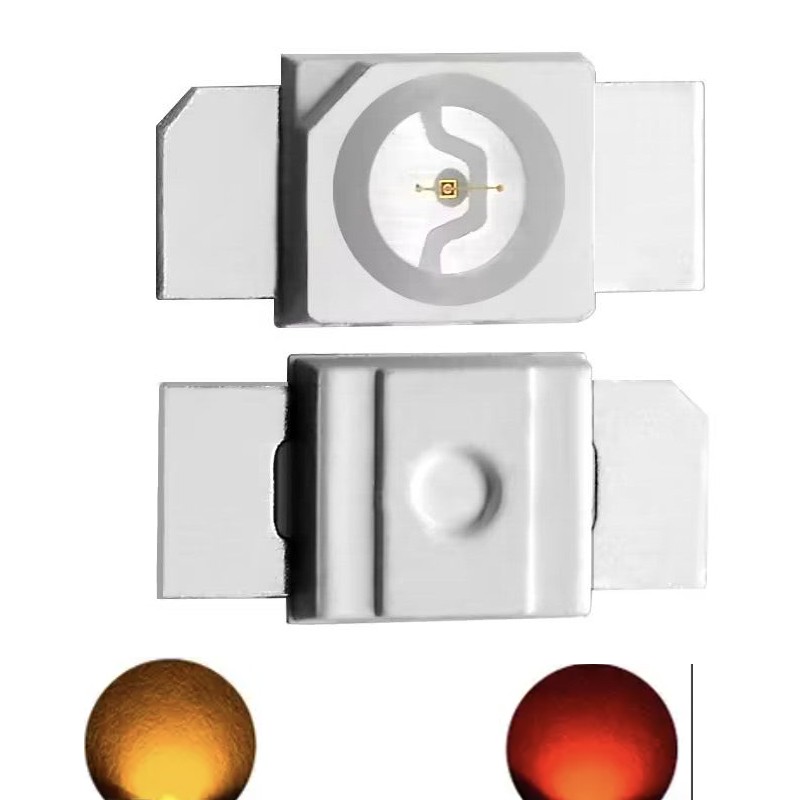

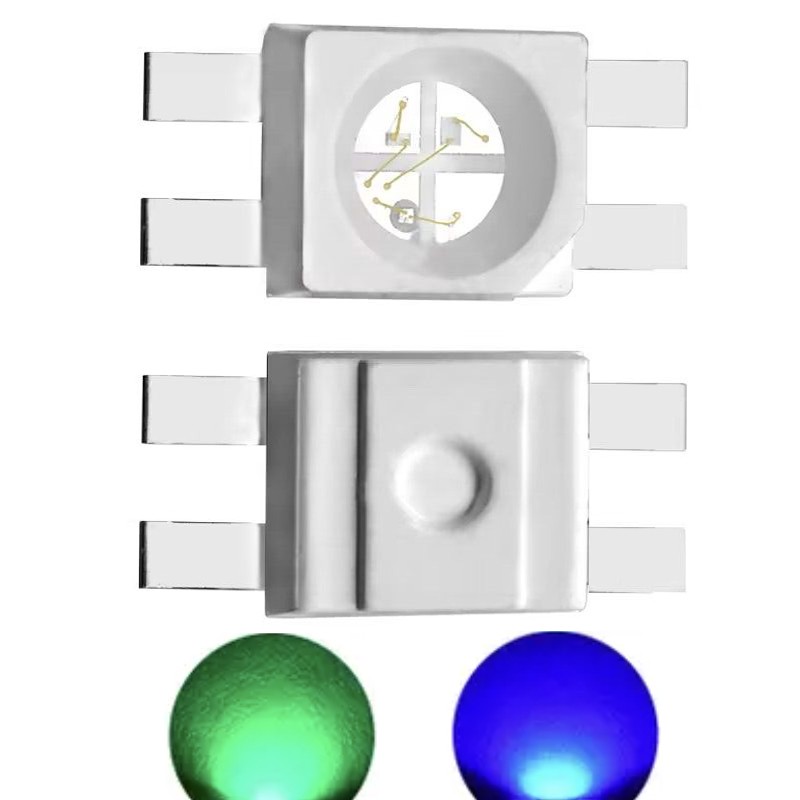

Reverse mount LED,3.2X2.8mm, variety of colors.

- Product Item : R3228X06YK

- Category: 3528 SMD LED

- Type: Reverse mount led

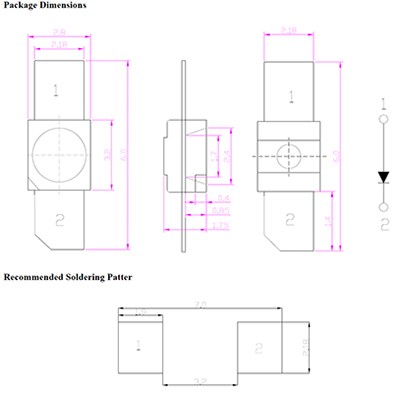

- Size: 3.2*2.8*1.75mm

- IF: 20mA

- View angle:120°

The reverse mount SMD LED is innovative LED which is designed to provide exceptional lighting solutions for a wide range of applications.It can be used to provide visual cues or signals in various electronic devices such as remote controls, power buttons, and panel displays. Additionally, its vibrant colors make it an ideal choice for decorative lighting in architectural projects, signage, and displays.Its compact size of 3.2X2.8mm, our reverse mount LED is perfect for projects that require small and discreet lighting components. Whether you are working on a small-scale electronic device or a larger installation, this LED can easily fit into any space without compromising on brightness.

Band:ARKTECH

Model:R3228X06YK

WL:R:620-630NM/red;520-30NM/Green;465-470NM/Blue; 3000K/warm white, 4500K/Natural white, 6500k/pure white and RGB.

Lumen: High Lumens

Power:0.2W/Color

Current:60MA

Voltage: R:2.0-2.2V/G B W:3.0-3.2V

Degree: 120

Raw material: Copper bracket / pure gold wire

Size:3.2*2.8*1.75 MM

If you need other SMD LED, please check our product categories.

Understanding the Basics of LED Chip Technology

LED chip technology is a semiconductor form of lighting, that uses electrically charged semiconductor chips to convert electrical energy into light. LEDs use less power than traditional light sources, such as incandescent bulbs, and are more cost-effective and energy-efficient.

LED chips are composed of a semiconductor material, typically a compound of aluminum, gallium, arsenic, and nitrogen. These semiconductor chips have an electrode at each end. One electrode is positively charged, and the other one is negatively charged. When an electrical current passes through the chip, electrons move across the semiconductor, creating a current of electrons that emit energy in the form of light. The amount of energy created by the current determines the color and brightness of the LED.

LED chips come in various shapes, sizes, and intensities. The performance of an LED chip is determined by the semiconductor material used in its construction, how much current is passed through it, and its encapsulation. The current, or intensity of the LED, is expressed in mA, milliamps, or milliamps per watt (mW).

LED chip technology is used in a variety of applications, such as automotive headlights, smartphone displays, laptop screens, and television screens. It is also a popular choice for commercial lighting applications given its long life, energy-efficiency, and cost-effectiveness.

How LED Chips Provide Energy-Efficient Lighting Solutions

LED chips provide energy-efficient lighting solutions by using less electricity to produce the same amount of light as traditional incandescent bulbs or CFLs. Their efficiency is measured in lumens per watt (lm/W). LEDs typically have efficiencies equal to or greater than 60 lumens per watt, which is significantly higher than the 15 to 20 lumens per watt produced by a traditional incandescent bulb. Additionally, LED chips have a much longer lifespan than traditional bulbs, meaning they can be used for extended periods of time without needing to be replaced. The increased efficiency and longer lifespan of LED chips result in considerable energy-saving benefits. These advantages have made LEDs increasingly popular for both residential and commercial lighting solutions.

Reverse mount LED-An Ultimate FAQ Guide:

2.About the scale of Reverse mount LED factory

3.About Reverse mount LED payment method

4.About Reverse mount LED production management system

5.About Reverse mount LED warranty

6.About Reverse mount LED patent

7.About Reverse mount LED customization services

1.About Reverse mount LED production equipment

Our factory comprises three production departments, housing a total of 12 production lines. We have equipped these lines with over 120 automatic machines from renowned brands such as ASM and Kaijo.

2.About the scale of Reverse mount LED factory

Our factory covers an area of 12000㎡, including a 600㎡ 10k class dust-free, anti-static workshop.

3.About Reverse mount LED payment method

We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit).

4.About Reverse mount LED production management system

We have implemented a robust production management system that leverages our ERP system, specifically incorporating material information, BOM information, and supplier information. This system allows us to monitor equipment control and production stability in real-time through the MES system.

5.About Reverse mount LED warranty

We provide a warranty period of 2 years .

6.About Reverse mount LED patent

Over the years, we have dedicated significant resources to research and innovation, resulting in the acquisition of more than 24 patents. Our factory has been recognized as a high tech manufacturer in the Jiangsu province.

7.About Reverse mount LED customization services

We welcome customization requests for our products.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Ms.Wendy

Mobile:0086-15861679389

Tel:0086-81725657

Whatsapp:0086 17386542651

Email:info@arktechcn.com

Add:8# HengDa CaiFu Center, JinKai Industrial Area, Wuci City, Jiang Su, China