circular pcb board for smd led

- Category: 2016 SMD LED

- Brand:ARKTECH

- delivery date: 7 to 9 working days

- payment method: We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit)

- Our team offers all-round technical support, including designing according to your requirements, selecting the best solutions based on cost and reliability, principle and LAY-OUT design, customizing s

Our products are available with international RoHS, CE,REACH and SGS certificates. Moreover, our powerful engineering team can improve our OEM services for clients continuously.

| Product name | circular pcb board for smd led |

| Keyword | 5050 smd led red,5050 smd led components,smd led for led bulb,4014 smd led lumens,e46 smd led angel eyes,dip pcb assembly smd led,cool white 6000k led strip smd led 5050,cree smd led chip |

| Place of Origin | China |

| Brand | ARKTECH |

| Current | 86MA |

| Power | 1.3W |

| Voltage | 3.1V |

| Raw material | Copper bracket/ pure gold wire |

| Quantity | 2893pcs/reel |

| Dimensions | 5.2mm*4.5mm*2mm, (Contact us for specific information to confirm) |

| Applicable Industries | household appliances, etc. |

| Color | green |

| Weight | 11mg |

| Product Description | 0201 smd led,3w smd led in india,4 leg smd led,402 smd led,SMD 5730 LED Green 0.5W chip,5 smd led t10-It is a new surface packaging technology that encapsulates LED chips in tiny weldable packaging films and performs surface spot welding on the PCB substrate, thus improving the reliability and production efficiency of LEDs. Compared with traditional LED packaging, SMD LED has the advantages of small size, large light-emitting area, high power, low packaging height, and multiple color temperatures, and can greatly reduce costs through automated production processes. |

| delivery date | Our standard delivery time is 7 to 9 working days. |

| payment method | We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit). |

| Life span | 53076 + hours (Contact us for specific information to confirm) |

| warranty | We provide a warranty period of 2 years |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Packing | 15x15.1x13.3mm(Contact us for specific information to confirm) |

| Sales country | All over the world for example:North Korea,Georgia,Kiribati,Niger,Lebanon,Afghanistan,Panama,Saint Kitts and Nevis |

| MOQ | 2 reel(Contact us for specific information to confirm) |

| customization services | We welcome customization requests for our products |

| production capacity | We have the capacity to produce 87kk pieces of LEDs per month. |

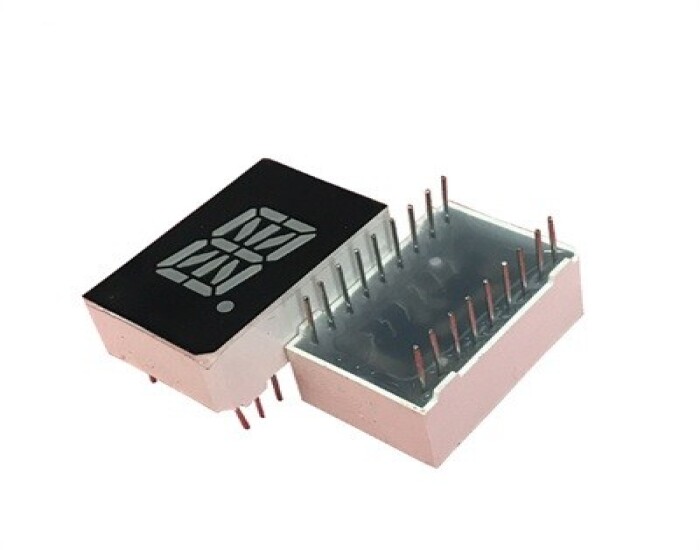

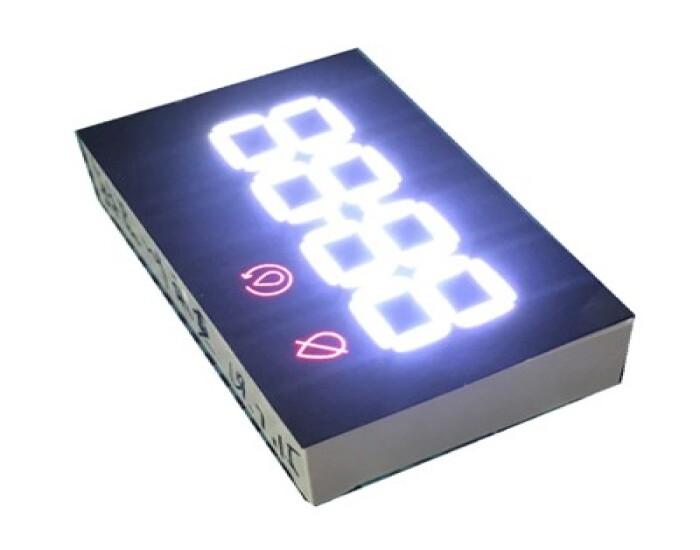

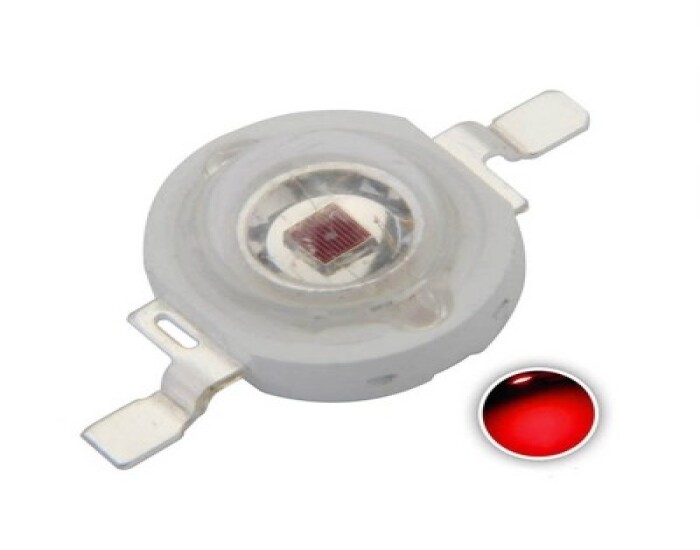

Segment led display, Custom LED display, Through hole LED, High power LED(Please contact us for specific information about Segment led display)

circular pcb board for smd led services FAQs Guide

Are you looking for a quick review guide about circular pcb board for smd ledservices?

An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding circular pcb board for smd led services.

Let’s continue!

2.What are the main applications of circular pcb board for smd led?

3.How does the efficiency of circular pcb board for smd led compare to other lighting options?

4.About circular pcb board for smd led raw material procurement system

5.About circular pcb board for smd led production skills training

6.How does the cost of circular pcb board for smd led compare to other types of lighting?

7.What is the difference between circular pcb board for smd led and COB LED?

8.How does circular pcb board for smd led emit light compared to other types of LEDs?

9.How does the size of circular pcb board for smd led affect its performance?

1.Are there any size limitations for circular pcb board for smd led?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

There are no specific size limitations for SMD LED, as they can be manufactured in various sizes and shapes to suit different applications. However, the smaller the size of the LED, the more challenging it is to manufacture and handle, which can affect its performance and reliability. Generally, SMD LEDs range from 0.2mm to 5mm in size.

2.What are the main applications of circular pcb board for smd led?

We are centered on customers and always pay attention to customers' needs for circular pcb board for smd led products.

1. Consumer Electronics: SMD LEDs are widely used in consumer electronics such as smartphones, laptops, TVs, and other electronic devices for backlighting, indicator lights, and display screens.

2. Automotive Lighting: SMD LEDs are used in automotive lighting for headlights, taillights, turn signals, and interior lighting due to their small size, energy efficiency, and long lifespan.

3. Signage and Displays: SMD LEDs are commonly used in signage and displays for their bright and vibrant colors, making them ideal for advertising and information displays.

4. General Lighting: SMD LEDs are increasingly being used in general lighting applications such as residential and commercial lighting due to their energy efficiency, long lifespan, and ability to produce a wide range of colors.

5. Medical Equipment: SMD LEDs are used in medical equipment for their small size, low heat emission, and ability to produce specific wavelengths of light for medical procedures and treatments.

6. Industrial Applications: SMD LEDs are used in various industrial applications such as machine vision, inspection, and process control due to their small size, low power consumption, and high brightness.

7. Entertainment and Stage Lighting: SMD LEDs are commonly used in entertainment and stage lighting for their ability to produce a wide range of colors and their compact size, making them ideal for creating dynamic lighting effects.

3.How does the efficiency of circular pcb board for smd led compare to other lighting options?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced circular pcb board for smd led products.

SMD LED (Surface Mount Device Light Emitting Diode) is a type of LED technology that is commonly used in lighting applications. Compared to other lighting options, SMD LED has several advantages in terms of efficiency.

1. Energy Efficiency: SMD LED lights are highly energy efficient, consuming up to 80% less energy than traditional incandescent bulbs. This means that they can produce the same amount of light while using significantly less electricity, resulting in lower energy bills.

2. Long Lifespan: SMD LED lights have a longer lifespan compared to other lighting options. They can last up to 50,000 hours, which is significantly longer than incandescent bulbs (1,000 hours) and CFL bulbs (8,000 hours). This means that SMD LED lights need to be replaced less frequently, resulting in cost savings in the long run.

3. Instant On: Unlike CFL bulbs, SMD LED lights do not require time to warm up and reach their full brightness. They turn on instantly, making them a more convenient option for lighting.

4. Directional Lighting: SMD LED lights emit light in a specific direction, unlike traditional bulbs that emit light in all directions. This makes them more efficient as there is less wasted light, and the light can be directed to where it is needed.

5. Low Heat Emission: SMD LED lights produce very little heat compared to incandescent and CFL bulbs. This not only makes them safer to use but also reduces the load on air conditioning systems, resulting in energy savings.

Overall, SMD LED lights are highly efficient and offer significant advantages over other lighting options in terms of energy consumption, lifespan, and convenience. They are also more environmentally friendly as they do not contain harmful substances such as mercury, which is found in CFL bulbs.

4.About circular pcb board for smd led raw material procurement system

Our production process is closely monitored through an ERP system and MES system, ensuring the stability and traceability of our products.

5.About circular pcb board for smd led production skills training

We require all our employees to undergo three months of training. Only after successfully passing a qualified test are they allowed to work on the production line. To further ensure the quality of our goods, we have implemented diagrams along the production line, providing clear instructions and guidelines. Additionally, our HD engineers conduct monthly training sessions to keep our team updated with the latest production techniques and practices.

6.How does the cost of circular pcb board for smd led compare to other types of lighting?

We continuously upgrade our skills and knowledge to adapt to changing circular pcb board for smd led market needs.

The cost of SMD LED (Surface Mount Device Light Emitting Diode) is generally higher than other types of lighting such as incandescent, fluorescent, and halogen lights. This is because SMD LEDs are more energy-efficient, have a longer lifespan, and offer better color rendering compared to traditional lighting options.

However, the cost of SMD LED has decreased significantly in recent years due to advancements in technology and increased production. In some cases, the initial cost of purchasing SMD LED lights may be higher, but the long-term savings in energy and maintenance costs make them a more cost-effective option.

Additionally, the cost of SMD LED varies depending on the brand, quality, and features of the light. Higher-end SMD LED lights with advanced features such as dimming capabilities or smart controls may be more expensive than basic SMD LED lights.

Overall, while the initial cost of SMD LED may be higher, the long-term savings and benefits make them a more cost-effective and efficient lighting option.

7.What is the difference between circular pcb board for smd led and COB LED?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market.

SMD LED (Surface Mount Device LED) and COB LED (Chip on Board LED) are two different types of LED technology used in lighting applications. The main differences between them are:

1. Design: SMD LEDs are small, individual LED chips mounted on a circuit board, while COB LEDs consist of multiple LED chips bonded directly to a substrate, creating a single module.

2. Size: SMD LEDs are smaller in size compared to COB LEDs, making them suitable for compact and slim lighting designs.

3. Light output: COB LEDs have a higher light output compared to SMD LEDs due to their larger size and higher number of LED chips.

4. Heat dissipation: COB LEDs have better heat dissipation capabilities compared to SMD LEDs, as the multiple LED chips are spread out over a larger surface area.

5. Color consistency: COB LEDs have better color consistency compared to SMD LEDs, as the multiple LED chips are closely packed together, resulting in a more uniform color output.

6. Cost: SMD LEDs are generally less expensive compared to COB LEDs, making them a more cost-effective option for lighting applications.

In summary, SMD LEDs are smaller, more affordable, and suitable for compact designs, while COB LEDs have a higher light output, better heat dissipation, and color consistency. The choice between the two will depend on the specific lighting needs and budget of the application.

8.How does circular pcb board for smd led emit light compared to other types of LEDs?

Our company has many years of circular pcb board for smd led experience and expertise.

SMD (Surface Mount Device) LEDs emit light in a similar way to other types of LEDs, but they have a different construction and packaging that allows for more efficient and compact use.

Like other LEDs, SMD LEDs use a semiconductor material, typically gallium nitride (GaN), to produce light when an electric current is applied. The semiconductor is sandwiched between two layers of different materials, called the p-type and n-type layers. When a voltage is applied to the LED, electrons from the n-type layer flow into the p-type layer, where they combine with positively charged holes" to produce light.

9.How does the size of circular pcb board for smd led affect its performance?

We have broad development space in domestic and foreign markets. circular pcb board for smd led have great advantages in terms of price, quality, and delivery date.

The size of an SMD LED can affect its performance in several ways:

1. Brightness: Generally, larger SMD LEDs have a higher maximum brightness compared to smaller ones. This is because larger LEDs have more surface area to emit light, allowing them to produce a brighter output.

2. Power consumption: Smaller SMD LEDs typically have a lower power consumption compared to larger ones. This is because smaller LEDs require less energy to produce the same amount of light as larger ones.

3. Heat dissipation: Larger SMD LEDs tend to generate more heat compared to smaller ones. This is because they have a higher power consumption and more surface area to dissipate heat. This can affect the overall performance and lifespan of the LED.

4. Viewing angle: The size of an SMD LED can also affect its viewing angle, which is the angle at which the light is emitted from the LED. Smaller LEDs typically have a narrower viewing angle, while larger LEDs have a wider viewing angle.

5. Durability: Larger SMD LEDs are generally more durable and have a longer lifespan compared to smaller ones. This is because they have a larger surface area, which allows for better heat dissipation and reduces the risk of overheating and damage.

Overall, the size of an SMD LED can significantly impact its performance, and it is essential to consider the specific requirements and applications when choosing the appropriate size for a particular project.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Ms.Wendy

Mobile:0086-15861679389

Tel:0086-81725657

Whatsapp:0086 17386542651

Email:info@arktechcn.com

Add:8# HengDa CaiFu Center, JinKai Industrial Area, Wuci City, Jiang Su, China