smd led production line

- Category: 2016 SMD LED

- Brand:ARKTECH

- delivery date: 7 to 9 working days

- payment method: We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit)

- Our team offers all-round technical support, including designing according to your requirements, selecting the best solutions based on cost and reliability, principle and LAY-OUT design, customizing s

| Product name | smd led production line |

| Keyword | ac 5050 smd led strip light stairs,3014 smd led wiki,smd led 3014 specifications,0804 smd led,1210 smd led watt,smd led anode cathode,g4 24 smd led warm white |

| Place of Origin | China |

| Brand | ARKTECH |

| Current | 112MA |

| Power | 1.1W |

| Voltage | 1.2V |

| Raw material | Copper bracket/ pure gold wire |

| Quantity | 2683pcs/reel |

| Dimensions | 4.1mm*5mm*2.3mm, (Contact us for specific information to confirm) |

| Applicable Industries | automotive filed, etc. |

| Color | purple |

| Weight | 10mg |

| Product Description | SMD LED 7020 Yellow Color 0.5W,SMD 5050 LED RGB 0.2W chip,SMD 5630 LED White 0.5W,01005 smd led-It is a new surface packaging technology that encapsulates LED chips in tiny weldable packaging films and performs surface spot welding on the PCB substrate, thus improving the reliability and production efficiency of LEDs. Compared with traditional LED packaging, SMD LED has the advantages of small size, large light-emitting area, high power, low packaging height, and multiple color temperatures, and can greatly reduce costs through automated production processes. |

| delivery date | Our standard delivery time is 7 to 9 working days. |

| payment method | We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit). |

| Life span | 52786 + hours (Contact us for specific information to confirm) |

| warranty | We provide a warranty period of 2 years |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Packing | 13x10.2x13.5mm(Contact us for specific information to confirm) |

| Sales country | All over the world for example:Solomon Islands,India,Reunion,El Salvador,Virgin Islands,Israel,Coral Sea Islands,Sudan |

| MOQ | 8 reel(Contact us for specific information to confirm) |

| customization services | We welcome customization requests for our products |

| production capacity | We have the capacity to produce 85kk pieces of LEDs per month. |

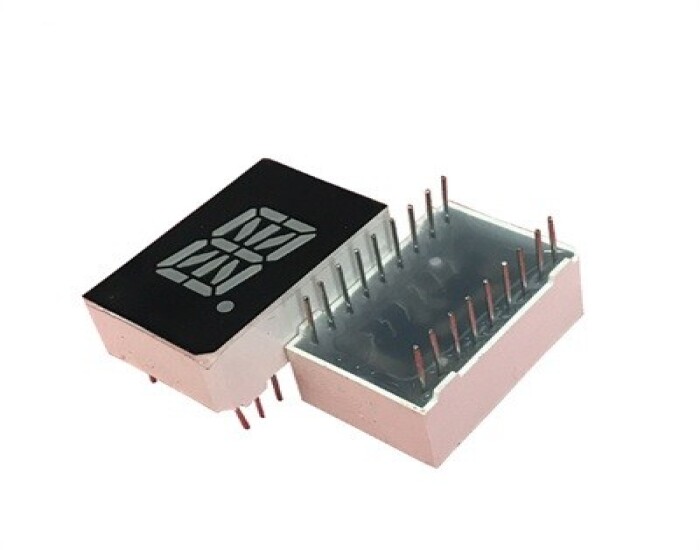

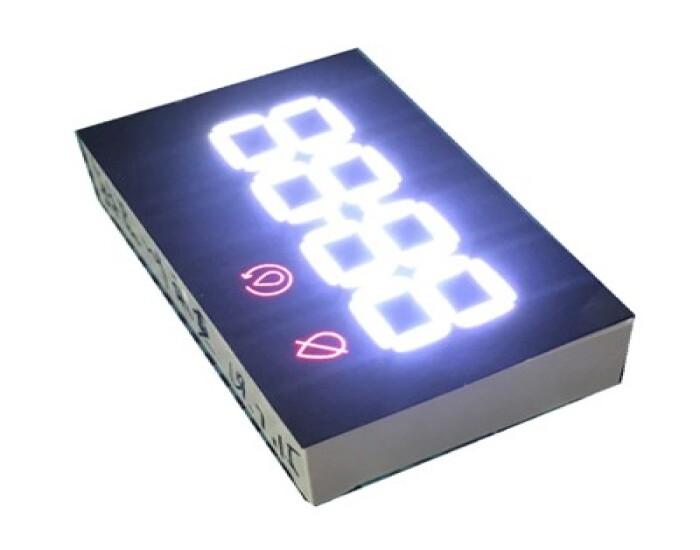

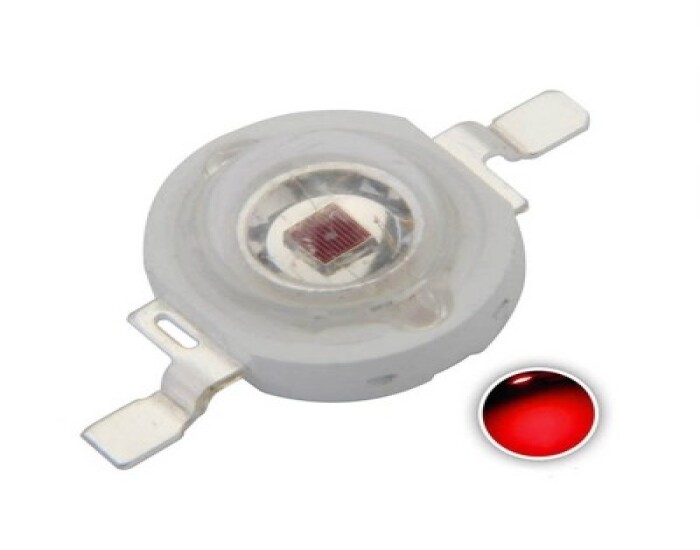

Segment led display, Custom LED display, Through hole LED, High power LED(Please contact us for specific information about Segment led display)

smd led production line services FAQs Guide

Are you looking for a quick review guide about smd led production lineservices?

An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding smd led production line services.

Let’s continue!

2.How does smd led production line hold up against extreme weather conditions?

3.How does smd led production line handle voltage fluctuations?

4.What is the difference between smd led production line and COB LED?

5.What is the warranty period for smd led production line?

6.About smd led production line production management system

7.Can smd led production line be used in hazardous locations?

8.About the scale of smd led production line factory

9.Does smd led production line produce any UV emissions?

10.Are there any size limitations for smd led production line?

11.How does smd led production line handle glare and eye strain?

1.Are there any maintenance requirements for smd led production line?

We focus on providing high smd led production line quality products and services.

Yes, there are some maintenance requirements for SMD LED:

1. Regular cleaning: Dust and dirt can accumulate on the surface of SMD LED, affecting its brightness and performance. It is important to regularly clean the LED with a soft, dry cloth to remove any dust or dirt.

2. Avoid moisture: SMD LED is sensitive to moisture and can get damaged if exposed to excessive moisture. It is important to keep the LED dry and avoid any contact with water.

3. Check for loose connections: SMD LED is soldered onto a circuit board, and over time, the connections can become loose due to vibrations or temperature changes. It is important to regularly check for loose connections and re-solder them if necessary.

4. Monitor heat dissipation: SMD LED can generate heat, and if not dissipated properly, it can affect its performance and lifespan. It is important to ensure that the LED is installed in a well-ventilated area and that any heat generated is dissipated efficiently.

5. Replace faulty LEDs: If any SMD LED is not functioning properly or has burnt out, it is important to replace it with a new one to maintain the overall performance of the LED system.

6. Follow manufacturer's instructions: It is important to follow the manufacturer's instructions for maintenance and care of SMD LED to ensure its optimal performance and longevity.

2.How does smd led production line hold up against extreme weather conditions?

We have established a good reputation and reliable partnerships within the smd led production line industry.

SMD LED (Surface Mount Device Light Emitting Diode) is designed to be more durable and resistant to extreme weather conditions compared to traditional LED lights. This is due to its compact size and construction, which allows it to withstand harsh environments and temperature fluctuations.

SMD LED lights are typically sealed with a silicone or epoxy resin, making them waterproof and dustproof. This protects the internal components from moisture, humidity, and other environmental factors that can cause damage to the LED.

In terms of extreme temperatures, SMD LED lights can operate in a wide range, from -40°C to 85°C. This makes them suitable for use in both hot and cold climates. They are also designed to withstand thermal shock, which is the sudden change in temperature that can cause damage to other types of LED lights.

Furthermore, SMD LED lights have a longer lifespan compared to traditional LED lights, making them more reliable in extreme weather conditions. They also have a lower failure rate and require less maintenance, making them a cost-effective option for outdoor and industrial applications.

Overall, SMD LED lights are highly durable and can hold up well against extreme weather conditions, making them a popular choice for outdoor and industrial lighting. However, it is always important to choose high-quality SMD LED lights from reputable manufacturers to ensure their performance and durability.

3.How does smd led production line handle voltage fluctuations?

We are committed to providing personalized solutions and established long -term strategic cooperative relationships with customers.

SMD LED (Surface Mount Device LED) is designed to handle voltage fluctuations by using a constant current driver. This driver regulates the current flowing through the LED, ensuring that the LED receives a consistent amount of power regardless of the voltage fluctuations. This helps to protect the LED from damage and maintain its brightness and lifespan. Additionally, SMD LEDs are also designed with built-in resistors that help to stabilize the voltage and prevent any sudden spikes or drops that could damage the LED.

4.What is the difference between smd led production line and COB LED?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market.

SMD LED (Surface Mount Device LED) and COB LED (Chip on Board LED) are two different types of LED technology used in lighting applications. The main differences between them are:

1. Design: SMD LEDs are small, individual LED chips mounted on a circuit board, while COB LEDs consist of multiple LED chips bonded directly to a substrate, creating a single module.

2. Size: SMD LEDs are smaller in size compared to COB LEDs, making them suitable for compact and slim lighting designs.

3. Light output: COB LEDs have a higher light output compared to SMD LEDs due to their larger size and higher number of LED chips.

4. Heat dissipation: COB LEDs have better heat dissipation capabilities compared to SMD LEDs, as the multiple LED chips are spread out over a larger surface area.

5. Color consistency: COB LEDs have better color consistency compared to SMD LEDs, as the multiple LED chips are closely packed together, resulting in a more uniform color output.

6. Cost: SMD LEDs are generally less expensive compared to COB LEDs, making them a more cost-effective option for lighting applications.

In summary, SMD LEDs are smaller, more affordable, and suitable for compact designs, while COB LEDs have a higher light output, better heat dissipation, and color consistency. The choice between the two will depend on the specific lighting needs and budget of the application.

5.What is the warranty period for smd led production line?

We actively participate in the smd led production line industry associations and organization activities. The corporate social responsibility performed well, and the focus of brand building and promotion The warranty period for SMD LED varies depending on the manufacturer and the specific product. Generally, the warranty period can range from 1 to 5 years. It is important to check with the manufacturer or retailer for the specific warranty period for the SMD LED product you are interested in purchasing.

6.About smd led production line production management system

We have implemented a robust production management system that leverages our ERP system, specifically incorporating material information, BOM information, and supplier information. This system allows us to monitor equipment control and production stability in real-time through the MES system.

7.Can smd led production line be used in hazardous locations?

We enjoy high authority and influence in the industry and continue to innovate products and service models.

No, SMD LED cannot be used in hazardous locations as they are not designed to withstand the potential risks and dangers present in these environments. Hazardous locations are defined as areas where flammable gases, vapors, or dusts may be present, and SMD LED may not have the necessary certifications or protections to operate safely in these conditions. It is important to use LED lighting specifically designed and certified for hazardous locations in these environments to ensure safety and compliance with regulations.

8.About the scale of smd led production line factory

Our factory covers an area of 12000㎡, including a 600㎡ 10k class dust-free, anti-static workshop.

9.Does smd led production line produce any UV emissions?

We operate our smd led production line business with integrity and honesty.

No, SMD LED does not produce any UV emissions. SMD LED lights use a semiconductor material to produce light, which does not emit UV radiation. However, some SMD LED lights may have a small amount of UV emissions due to the use of phosphors in the LED chip, but this is typically very low and not harmful to humans.

10.Are there any size limitations for smd led production line?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

There are no specific size limitations for SMD LED, as they can be manufactured in various sizes and shapes to suit different applications. However, the smaller the size of the LED, the more challenging it is to manufacture and handle, which can affect its performance and reliability. Generally, SMD LEDs range from 0.2mm to 5mm in size.

11.How does smd led production line handle glare and eye strain?

As one of the top smd led production line manufacturers in China, we take this very seriously.

SMD LED (Surface Mount Device Light Emitting Diode) technology is designed to reduce glare and eye strain compared to traditional LED lighting. This is achieved through several factors:

1. Diffusion: SMD LEDs are designed with a diffused lens that helps to spread the light evenly, reducing the intensity of the light and minimizing glare.

2. Directionality: SMD LEDs emit light in a specific direction, unlike traditional LEDs which emit light in all directions. This directional light helps to reduce glare and direct the light where it is needed.

3. Color temperature: SMD LEDs have a color temperature that is closer to natural daylight, which is easier on the eyes compared to the harsh blue light emitted by traditional LEDs.

4. Flicker-free: SMD LEDs are designed to be flicker-free, meaning they do not produce rapid fluctuations in light intensity that can cause eye strain and headaches.

5. Dimmability: SMD LEDs can be dimmed, allowing for customizable lighting levels that can be adjusted to reduce glare and eye strain.

Overall, SMD LED technology is designed to provide a more comfortable and natural lighting experience, reducing glare and eye strain for the user.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Ms.Wendy

Mobile:0086-15861679389

Tel:0086-81725657

Whatsapp:0086 17386542651

Email:info@arktechcn.com

Add:8# HengDa CaiFu Center, JinKai Industrial Area, Wuci City, Jiang Su, China