Industry-news

The Manufacturing Process of SMD LED

What is SMD LED?

SMD LED stands for Surface Mount Device Light-Emitting Diode. It is a type of LED that is mounted directly onto the surface of a printed circuit board (PCB) without the need for separate leads or wires. SMD LEDs are widely used in various applications, including lighting fixtures, automotive lighting, consumer electronics, signage, and more. SMD LEDs are highly versatile, compact, energy-efficient, and durable light sources that have revolutionized the lighting industry. Their ability to be easily mounted on PCBs with surface mount technology has made them a popular choice for various applications that require efficient, high-quality lighting solutions.

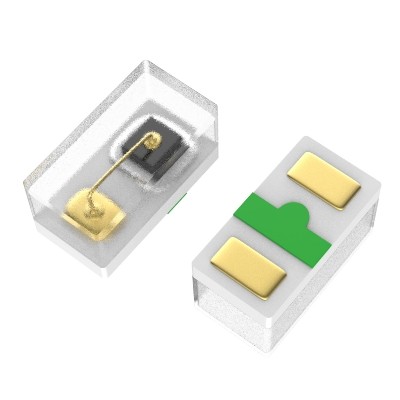

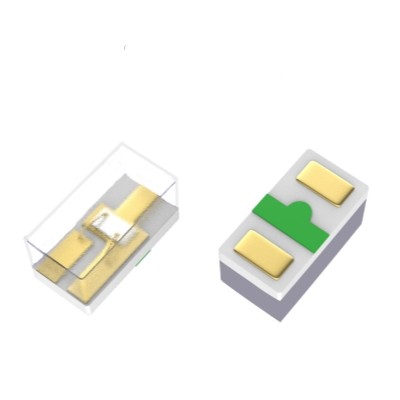

The construction of an SMD LED consists of a semiconductor chip that emits light when an electric current is applied to it. The chip is encapsulated in a small and compact package that can be easily soldered onto the PCB. This surface mount technology (SMT) eliminates the need for through-hole components and allows for efficient and automated manufacturing processes. SMD LEDs come in various sizes and shapes, such as 3528, 2835, or 5050, which corresponds to their dimensions in millimeters. The size of the SMD LED package determines its light output and power rating. For example, larger SMD LEDs tend to have higher brightness levels and power ratings.

One of the key advantages of SMD LEDs is their small size and low profile, which makes them suitable for applications with space constraints. Additionally, SMD LEDs offer improved thermal management due to their direct contact with the PCB, allowing for better heat dissipation. SMD LEDs also offer exceptional energy efficiency and long lifespans. They consume less power compared to traditional lighting sources, such as incandescent bulbs, while producing brighter and more focused light. With advancements in LED technology, SMD LEDs now offer a wide range of color options, including white, red, green, blue, and even RGB (red, green, blue) for color-changing effects.

The Manufacturing Process of SMD LED

Arktech, a renowned company in the LED industry, takes pride in its advanced manufacturing processes and commitment to delivering top-quality SMD LEDs (Surface Mount Device LEDs). With a focus on customer satisfaction, Arktech not only offers exceptional products but also provides comprehensive after-sales services. Let's delve into the various aspects of Arktech's SMD LED manufacturing process and explore the company's commitment to quality, compensation terms, color temperature, and maximum ratings.

PartⅠ: After-Sales Service:

Arktech values its customers and strives to offer excellent after-sales service. In the event of any issues or concerns with Arktech's SMD LEDs, our dedicated support team is readily available to provide assistance and rectify the situation promptly. Our aim is to ensure that our customers are fully satisfied with their purchase, and we are committed to resolving any concerns they may have.

PartⅡ: Quality Inspection:

At Arktech, maintaining the highest level of quality is of utmost importance. Our SMD LED manufacturing process includes stringent quality inspection procedures at every stage. From the selection of raw materials to the assembly and packaging, each step is closely monitored and evaluated for conformity to our rigorous quality standards. Only LEDs that pass our extensive quality checks are released for further processing, ensuring that our customers receive products of exceptional quality and reliability.

PartⅢ: Compensation Terms:

Arktech stands by the quality and reliability of its SMD LEDs. In the event of any manufacturing defect or performance issues, we offer comprehensive compensation terms to protect our customers' investment. Our compensation terms cover situations where the LEDs fail to meet the specified performance parameters or if there are any manufacturing-related defects. You can rely on Arktech's commitment to customer satisfaction and our willingness to address any concerns that may arise.

PartⅣ: Color Temperature:

Color temperature is a crucial factor when it comes to LED lighting. Arktech's SMD LEDs are available in a range of color temperatures to cater to various lighting requirements. By carefully controlling the manufacturing process, we ensure that our LEDs emit light at the desired color temperature, providing consistent and accurate lighting solutions for a wide range of applications. Whether you need warm white, cool white, or any other specific color temperature, Arktech has the right LED solution for you.

PartⅤ: Maximum Ratings:

To ensure the optimal performance and longevity of our SMD LEDs, Arktech sets maximum ratings for each product. These ratings define the limits within which the LEDs can safely operate without compromising their lifespan or performance. By adhering to these maximum ratings, customers can have peace of mind knowing that they are getting LEDs that are designed to operate within safe and reliable parameters, minimizing the risk of premature failure or diminished performance.

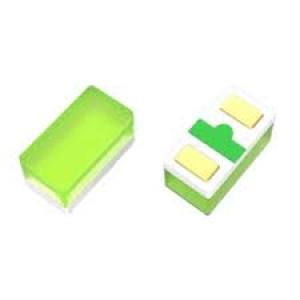

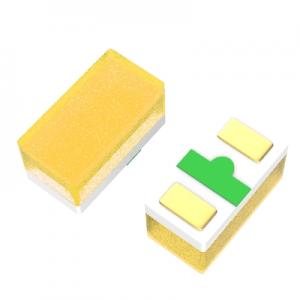

0201 SMD LED YELLOW GREEN Color

Cost Performance

Cost performance refers to the value or benefit derived from a product or service in relation to its cost. In the context of SMD LEDs, cost performance refers to how well the LED performs and meets the required specifications while considering its cost-effectiveness.

When it comes to SMD LEDs, cost performance is a critical factor in determining the overall value and suitability of the product for a particular application. Here are a few key aspects to consider when evaluating the cost performance of SMD LEDs:

①The efficiency of an SMD LED refers to the amount of light it produces for a given amount of electrical power consumed. A high-efficiency LED will result in cost savings over time by reducing energy consumption and lowering electricity bills. Therefore, choosing SMD LEDs with good energy efficiency ensures better cost performance.

②The lifespan of an LED has a direct impact on its cost performance. LEDs with longer lifespans require less frequent replacement, resulting in reduced maintenance and replacement costs. Opting for SMD LEDs with longer lifespans can provide better cost performance in the long run.

③When assessing the cost performance of SMD LEDs, it is vital to consider not only the initial cost but also factors such as energy efficiency, lifespan, reliability, and overall quality. By carefully evaluating these aspects, you can choose SMD LEDs that offer the best balance between performance and cost, resulting in optimal cost performance for your specific application.

CATEGORIES

LATEST NEWS

CONTACT US

Name: Ms.Wendy

Mobile:0086-15861679389

Tel:0086-81725657

Whatsapp:0086 17386542651

Email:info@arktechcn.com

Add:8# HengDa CaiFu Center, JinKai Industrial Area, Wuci City, Jiang Su, China