smd led board

- Category: 2016 SMD LED

- Brand:ARKTECH

- delivery date: 7 to 9 working days

- payment method: We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit)

- Our team offers all-round technical support, including designing according to your requirements, selecting the best solutions based on cost and reliability, principle and LAY-OUT design, customizing s

| Product name | smd led board |

| Keyword | dimmable 5730 smd led board,optik 90 smd led rechargeable work light,5 smd led t10,1 watt smd led specifications,smd led 3014,g9 smd led light bulb 2.5 watt,china smd led flexible strips |

| Place of Origin | China |

| Brand | ARKTECH |

| Current | 108MA |

| Power | 1.7W |

| Voltage | 0.4V |

| Raw material | Copper bracket/ pure gold wire |

| Quantity | 2689pcs/reel |

| Dimensions | 3.6mm*5.2mm*1.6mm, (Contact us for specific information to confirm) |

| Applicable Industries | urban lighting, etc. |

| Color | green |

| Weight | 6mg |

| Product Description | SMD 5050 LED 1.5W RGB chip,SMD LED 7020 Green Color 0.5W,0.5w smd led,SMD 7020 LED Blue 0.5w chip,0.5w smd led 3.v-It is a new surface packaging technology that encapsulates LED chips in tiny weldable packaging films and performs surface spot welding on the PCB substrate, thus improving the reliability and production efficiency of LEDs. Compared with traditional LED packaging, SMD LED has the advantages of small size, large light-emitting area, high power, low packaging height, and multiple color temperatures, and can greatly reduce costs through automated production processes. |

| delivery date | Our standard delivery time is 7 to 9 working days. |

| payment method | We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit). |

| Life span | 50278 + hours (Contact us for specific information to confirm) |

| warranty | We provide a warranty period of 2 years |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Packing | 17x13.52x15.6mm(Contact us for specific information to confirm) |

| Sales country | All over the world for example:Pitcairn Islands,Ethiopia,Argentina,Greenland,Jordan,Hungary,Lebanon |

| MOQ | 5 reel(Contact us for specific information to confirm) |

| customization services | We welcome customization requests for our products |

| production capacity | We have the capacity to produce 88kk pieces of LEDs per month. |

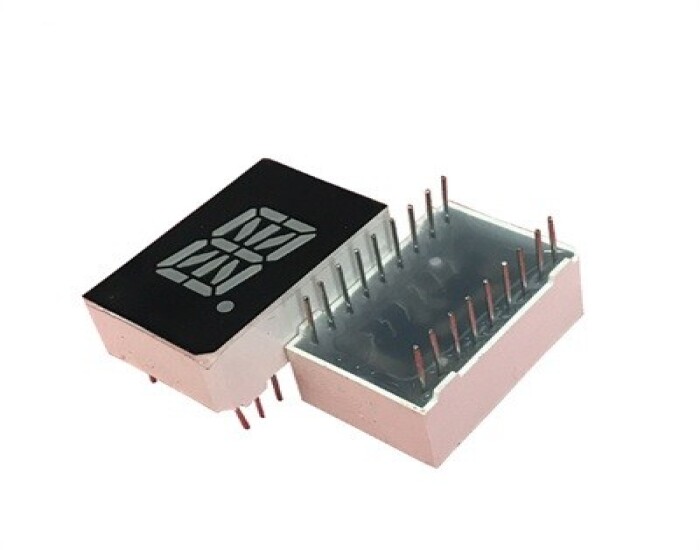

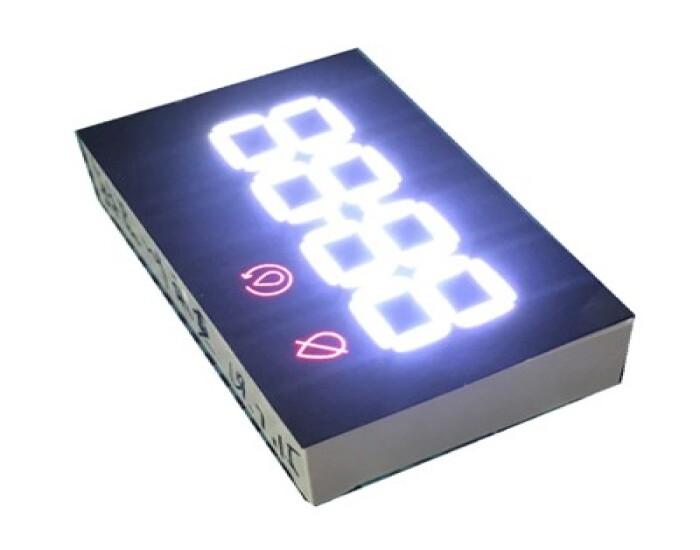

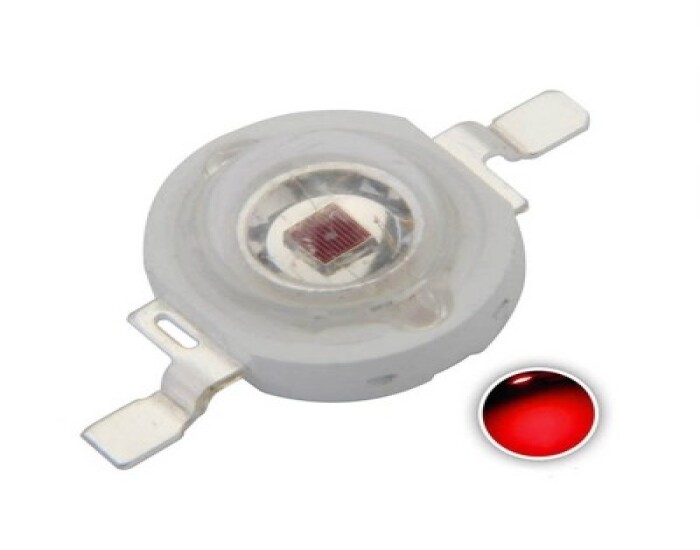

Segment led display, Custom LED display, Through hole LED, High power LED(Please contact us for specific information about Segment led display)

smd led board services FAQs Guide

Are you looking for a quick review guide about smd led boardservices?

An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding smd led board services.

Let’s continue!

2.What are the main applications of smd led board?

3.Can smd led board be used in outdoor settings?

4.What is the difference between smd led board and COB LED?

5.What are smd led board lights?

6.Can smd led board be used in hazardous locations?

7.Can smd led board be used in low voltage applications?

8.What is the color rendering index (CRI) of smd led board?

9.How does the luminous efficacy of smd led board compare to other LEDs?

10.Are there any environmental considerations when using smd led board?

11.Is smd led board resistant to shock and vibration?

12.How does smd led board handle heat dissipation?

13.About smd led board R&D capabilities

14.How does the cost of smd led board compare to other types of lighting?

1.About the scale of smd led board factory

Our factory covers an area of 12000㎡, including a 600㎡ 10k class dust-free, anti-static workshop.

2.What are the main applications of smd led board?

We are centered on customers and always pay attention to customers' needs for smd led board products.

1. Consumer Electronics: SMD LEDs are widely used in consumer electronics such as smartphones, laptops, TVs, and other electronic devices for backlighting, indicator lights, and display screens.

2. Automotive Lighting: SMD LEDs are used in automotive lighting for headlights, taillights, turn signals, and interior lighting due to their small size, energy efficiency, and long lifespan.

3. Signage and Displays: SMD LEDs are commonly used in signage and displays for their bright and vibrant colors, making them ideal for advertising and information displays.

4. General Lighting: SMD LEDs are increasingly being used in general lighting applications such as residential and commercial lighting due to their energy efficiency, long lifespan, and ability to produce a wide range of colors.

5. Medical Equipment: SMD LEDs are used in medical equipment for their small size, low heat emission, and ability to produce specific wavelengths of light for medical procedures and treatments.

6. Industrial Applications: SMD LEDs are used in various industrial applications such as machine vision, inspection, and process control due to their small size, low power consumption, and high brightness.

7. Entertainment and Stage Lighting: SMD LEDs are commonly used in entertainment and stage lighting for their ability to produce a wide range of colors and their compact size, making them ideal for creating dynamic lighting effects.

3.Can smd led board be used in outdoor settings?

We should perform well in market competition, and the prices of smd led board products have a great competitive advantage.

Yes, SMD (Surface Mount Device) LED lights can be used in outdoor settings. They are commonly used in outdoor lighting applications such as street lights, flood lights, and landscape lighting. SMD LEDs are designed to be durable and weather-resistant, making them suitable for outdoor use. However, it is important to ensure that the SMD LED lights are rated for outdoor use and are properly installed to withstand harsh weather conditions.

4.What is the difference between smd led board and COB LED?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market.

SMD LED (Surface Mount Device LED) and COB LED (Chip on Board LED) are two different types of LED technology used in lighting applications. The main differences between them are:

1. Design: SMD LEDs are small, individual LED chips mounted on a circuit board, while COB LEDs consist of multiple LED chips bonded directly to a substrate, creating a single module.

2. Size: SMD LEDs are smaller in size compared to COB LEDs, making them suitable for compact and slim lighting designs.

3. Light output: COB LEDs have a higher light output compared to SMD LEDs due to their larger size and higher number of LED chips.

4. Heat dissipation: COB LEDs have better heat dissipation capabilities compared to SMD LEDs, as the multiple LED chips are spread out over a larger surface area.

5. Color consistency: COB LEDs have better color consistency compared to SMD LEDs, as the multiple LED chips are closely packed together, resulting in a more uniform color output.

6. Cost: SMD LEDs are generally less expensive compared to COB LEDs, making them a more cost-effective option for lighting applications.

In summary, SMD LEDs are smaller, more affordable, and suitable for compact designs, while COB LEDs have a higher light output, better heat dissipation, and color consistency. The choice between the two will depend on the specific lighting needs and budget of the application.

5.What are smd led board lights?

Our smd led board products undergo strict quality control to ensure customer satisfaction.

SMD LED lights are a type of LED (light-emitting diode) light that uses surface-mount technology (SMT) to mount the LED chips onto a circuit board. This allows for a more compact and efficient design, as well as a wider range of color options. SMD LED lights are commonly used in electronic devices, automotive lighting, and general lighting applications. They are known for their energy efficiency, long lifespan, and low heat emission.

6.Can smd led board be used in hazardous locations?

We enjoy high authority and influence in the industry and continue to innovate products and service models.

No, SMD LED cannot be used in hazardous locations as they are not designed to withstand the potential risks and dangers present in these environments. Hazardous locations are defined as areas where flammable gases, vapors, or dusts may be present, and SMD LED may not have the necessary certifications or protections to operate safely in these conditions. It is important to use LED lighting specifically designed and certified for hazardous locations in these environments to ensure safety and compliance with regulations.

7.Can smd led board be used in low voltage applications?

We have a wide range of smd led board customer groups and establishes long -term cooperative relationships with partners. The countries we provide services include Pitcairn Islands,Ethiopia,Argentina,Greenland,Jordan,Hungary,Lebanon.

Yes, SMD (Surface Mount Device) LED can be used in low voltage applications. In fact, SMD LED is commonly used in low voltage applications such as in electronic devices, automotive lighting, and decorative lighting. SMD LED typically operates at a voltage range of 2-3.6V, making it suitable for low voltage applications. Additionally, SMD LED has a compact size and low power consumption, making it ideal for use in low voltage circuits.

8.What is the color rendering index (CRI) of smd led board?

Our smd led board products have competitive and differentiated advantages, and actively promote digital transformation and innovation. The color rendering index (CRI) of SMD LED can vary depending on the specific type and brand, but generally ranges from 70 to 90. Some high-quality SMD LEDs may have a CRI of 95 or higher.

9.How does the luminous efficacy of smd led board compare to other LEDs?

We should enjoy a good reputation in the industry, and we can increase the added value of the products of cooperative customers through technological innovation.

SMD (Surface Mount Device) LEDs have a higher luminous efficacy compared to other types of LEDs. This is because SMD LEDs have a smaller size and can be densely packed on a circuit board, allowing for more efficient use of light output. Additionally, SMD LEDs have a higher color rendering index (CRI) which means they can produce a wider range of colors and more accurate color representation. Overall, SMD LEDs have a luminous efficacy that is comparable to other high-efficiency LEDs such as COB (Chip on Board) and high-power LEDs.

10.Are there any environmental considerations when using smd led board?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

Yes, there are several environmental considerations when using SMD LED:

1. Energy Efficiency: SMD LED lights are highly energy-efficient, consuming less electricity compared to traditional incandescent or fluorescent lights. This reduces the overall energy consumption and helps in reducing carbon emissions.

2. Toxic Materials: Some SMD LED lights contain toxic materials such as lead, mercury, and arsenic, which can be harmful to the environment if not disposed of properly. It is important to recycle these lights properly to prevent these toxic materials from entering the environment.

3. E-waste: SMD LED lights are electronic devices and can contribute to the growing problem of e-waste. It is important to dispose of them properly to prevent them from ending up in landfills and polluting the environment.

4. Light Pollution: SMD LED lights can contribute to light pollution, which can disrupt the natural cycles of plants and animals and affect their behavior. It is important to use SMD LED lights responsibly and avoid unnecessary lighting to reduce light pollution.

5. Manufacturing Process: The manufacturing process of SMD LED lights can also have an impact on the environment. It requires a significant amount of energy and resources, and the disposal of waste materials can also be a concern. Choosing SMD LED lights from manufacturers with sustainable and environmentally friendly practices can help reduce the environmental impact.

6. End-of-life Disposal: When SMD LED lights reach the end of their lifespan, they need to be disposed of properly. If not recycled or disposed of correctly, they can release toxic materials into the environment. It is important to follow proper disposal guidelines and recycle SMD LED lights to reduce their environmental impact.

11.Is smd led board resistant to shock and vibration?

We have the leading technology and innovation capabilities, and attach importance to employee training and development, and provide promotion opportunities.

Yes, SMD LED (Surface Mount Device Light Emitting Diode) is generally resistant to shock and vibration. This is because SMD LEDs are mounted directly onto a circuit board, which provides stability and protection against external forces. Additionally, SMD LEDs do not have any moving parts, making them less susceptible to damage from shock and vibration. However, excessive or prolonged shock and vibration can still potentially damage SMD LEDs, so it is important to handle them with care.

12.How does smd led board handle heat dissipation?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced smd led board products.

SMD (Surface Mount Device) LED chips are designed to handle heat dissipation in several ways:

1. Heat Sink: SMD LEDs are often mounted on a heat sink, which is a metal plate or structure that helps to dissipate heat away from the LED chip. The heat sink provides a larger surface area for heat to dissipate, allowing the LED to operate at a lower temperature.

2. Thermal Pad: Some SMD LEDs have a thermal pad on the bottom of the chip, which helps to transfer heat away from the LED and onto the heat sink.

3. Thermal Via: SMD LEDs may also have thermal vias, which are small holes in the PCB (printed circuit board) that allow heat to transfer from the LED chip to the other side of the board, where it can be dissipated.

4. Copper Traces: The PCB may also have copper traces that act as heat sinks, helping to dissipate heat away from the LED chip.

5. Encapsulation: SMD LEDs are often encapsulated in a material that helps to dissipate heat, such as silicone or epoxy. This material also protects the LED chip from external factors that could affect its performance.

Overall, SMD LEDs are designed to efficiently dissipate heat and maintain a low operating temperature, which helps to prolong their lifespan and maintain their performance.

13.About smd led board R&D capabilities

Our team consists of 22 PD engineers and 15 PE engineers with more than 10 years of experience.

14.How does the cost of smd led board compare to other types of lighting?

We continuously upgrade our skills and knowledge to adapt to changing smd led board market needs.

The cost of SMD LED (Surface Mount Device Light Emitting Diode) is generally higher than other types of lighting such as incandescent, fluorescent, and halogen lights. This is because SMD LEDs are more energy-efficient, have a longer lifespan, and offer better color rendering compared to traditional lighting options.

However, the cost of SMD LED has decreased significantly in recent years due to advancements in technology and increased production. In some cases, the initial cost of purchasing SMD LED lights may be higher, but the long-term savings in energy and maintenance costs make them a more cost-effective option.

Additionally, the cost of SMD LED varies depending on the brand, quality, and features of the light. Higher-end SMD LED lights with advanced features such as dimming capabilities or smart controls may be more expensive than basic SMD LED lights.

Overall, while the initial cost of SMD LED may be higher, the long-term savings and benefits make them a more cost-effective and efficient lighting option.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Ms.Wendy

Mobile:0086-15861679389

Tel:0086-81725657

Whatsapp:0086 17386542651

Email:info@arktechcn.com

Add:8# HengDa CaiFu Center, JinKai Industrial Area, Wuci City, Jiang Su, China